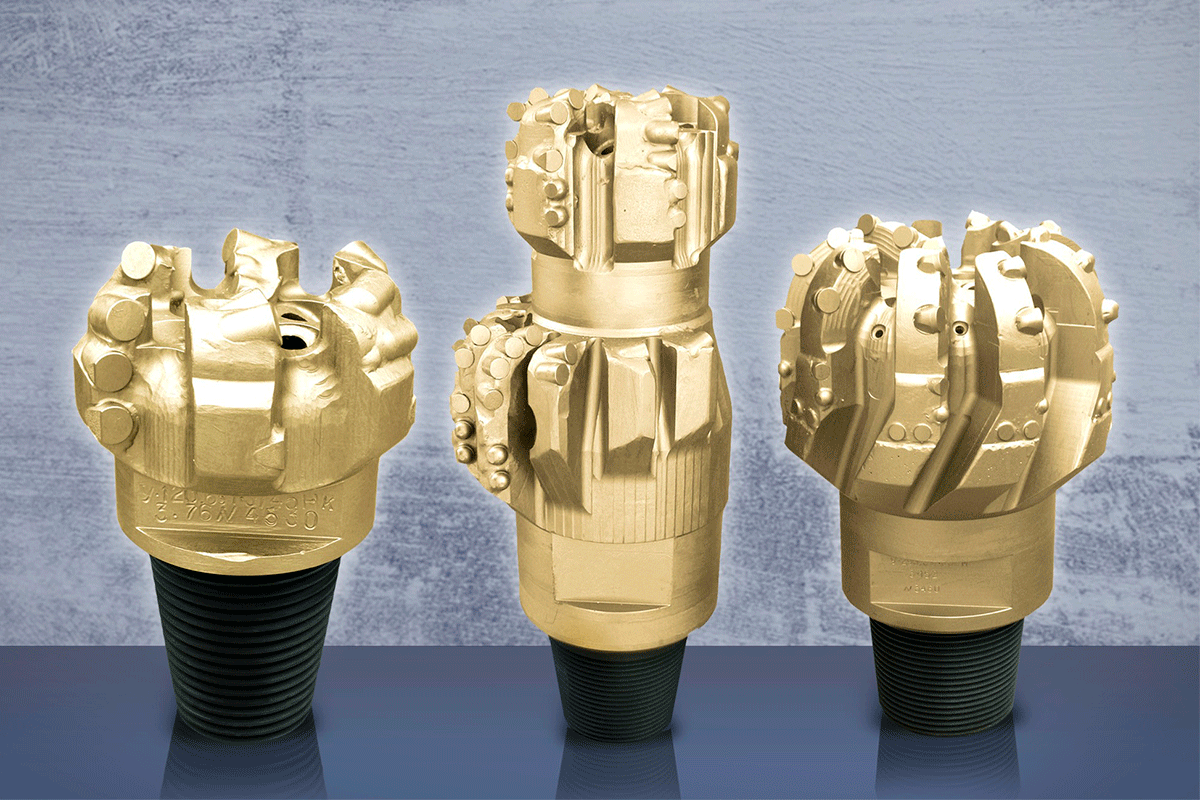

Inteco BUR applies modern drill bits

The drill bits have a special design that allows boring rocks of various hardness, and prevent formation of cake.

Moreover, all equipment is made of high quality materials resistive to corrosion.

Directional wells become very common within the Yamal peninsula which result in increased demand for specific drilling tools from clients. For example, 393.7 mm FD 268 SMA 56 drill bit of domestic manufacturing is designed for continuous drilling of vertical and directional wells in soft formations. The drill bit has helical cutting blades that facilitate transportation of cuttings out of the bottomhole and its cleaning. Availability of special teeth at the sizing part increase resistance of the drill bit to wear and tear.

300.0 mm T 5719 ZMS086 drill bit manufactured by BTK is designed for continuous drilling and has a unique cutting structure that makes the drill bit robust and decreases its wear and tear from impact stress and decreases their ingress into the rock.

Specially designed drill bit is suitable for drilling of vertical and directional oil and gas wells in soft rocks with medium hardness interlayers. The above listed characteristics allow performing high quality and high efficiency operations at the clients’ facilities.

Return to news