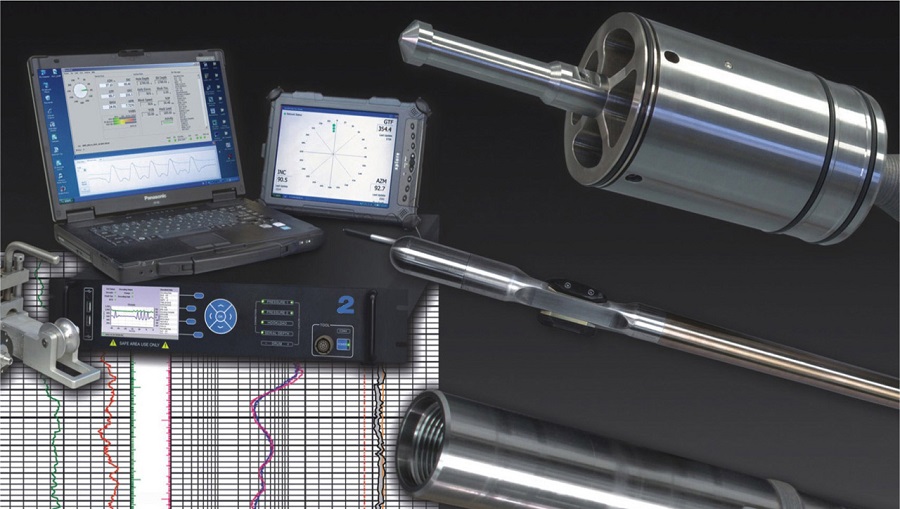

Inteco BUR uses certified telemetering equipment

Modern technologies are applied for slant-hole directional drilling and extended reach drilling.

According to the company director of difficult wells engineeringand drilling department, whatever the required telemetering types and production tests are, this equipment allows shortening of drilling time and minimizing dogleg severity.

– While drilling measuring equipment (MWD) and logging tools(LWD) provide the specialists with the data required fornavigation and reservoir properties estimation, – explained Inteco BUR expert. – In order to support business objectives such modern systems as meter detectors for various drilling parameters with fast data track to surface and with high density when fast drilling are applied. They allow obtaining reliable andaccurate measurements on a real time basis for major drilling methods.

High output drilling of difficult wells imposes specificrequirements to the equipment: online data transmission, permanent measuring at drill bit, vibration level shock loads detection, measuring of bit speed, zenith and horizontal angles automatic hold mode.

Such tasks can be performed by rotary controlled systems (RCS). The equipment allows wells drilling with smootherprofile without pipe bend with extended reach due to reducing friction and better hole cleaning.

The boring higher speed with permanent drill pipe rotation guards against any possibility of drilling instrument sticking; reduces time needed for removing cuttings from hole and any impact of drill mud on producing reservoir and provides faster brining-in of wells.

Return to news